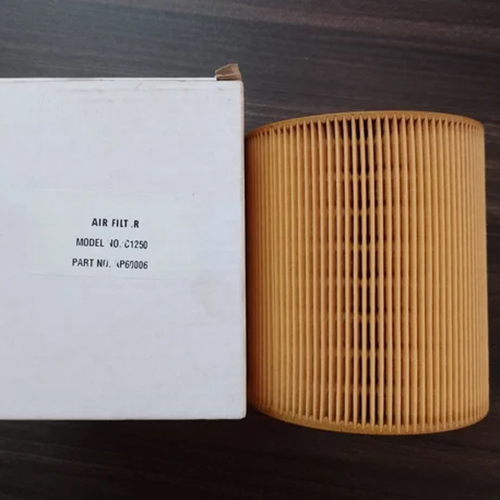

Air Filter For Atlas Copco

1100 INR/Piece

Product Details:

X

Air Filter For Atlas Copco Price And Quantity

- 10 Piece

- 1100 INR/Piece

Air Filter For Atlas Copco Trade Information

- 1-7 Days

Product Description

We offer 100% imported lubricant as replacement for lubricant used in Atlas-Copco Rotary Screw Air Compressors and Chicago Pneumatic Rotary Screw Air Compressors. It is 100 % compatible with the lubricant & is completely mixable with the lubricant supplied by the O.E.M.SPECIFICATIONS:

ISO DP 6521, DIN 51506 VDL certification for the use in screw air compressors.

NF-ISO 6743 classified DAJ for heavy duty applications

OEMS: Atlas Copco, CompAir, Hydrovane,

ADVANTAGES:

Compressor efficiency Optimized.

Avoids the carbon build up.

Allows a good oil/air and oil/condensates separation.

Operating cost minimized.

Extending the drain intervals.

The possible achieved drain intervals can be: - 1000 hours for field compressors.

From 2500 to 3500 hours for fixed compressors in standard use, and up to 4500 hours with lubricant analysis monitoring.

Extending the service life of the separating filter elements

Has an anti-clogging property that ensures the efficiency of the filters during a long period (up to 6000 hours).

Enter Buying Requirement Details